Northern British Columbia – Transmission Tower Replacement

The Project

Allteck was required to raise the wire height to accommodate Shell Canada transporting new LNG modules to build an LNG terminal. The scope of the work included replacing a double circuit 287kV lattice tower with four 220’ single circuit steel H-Frame towers in order to raise the conductors well above the road surface to allow for large load transportation from the dock facility.

Challenges

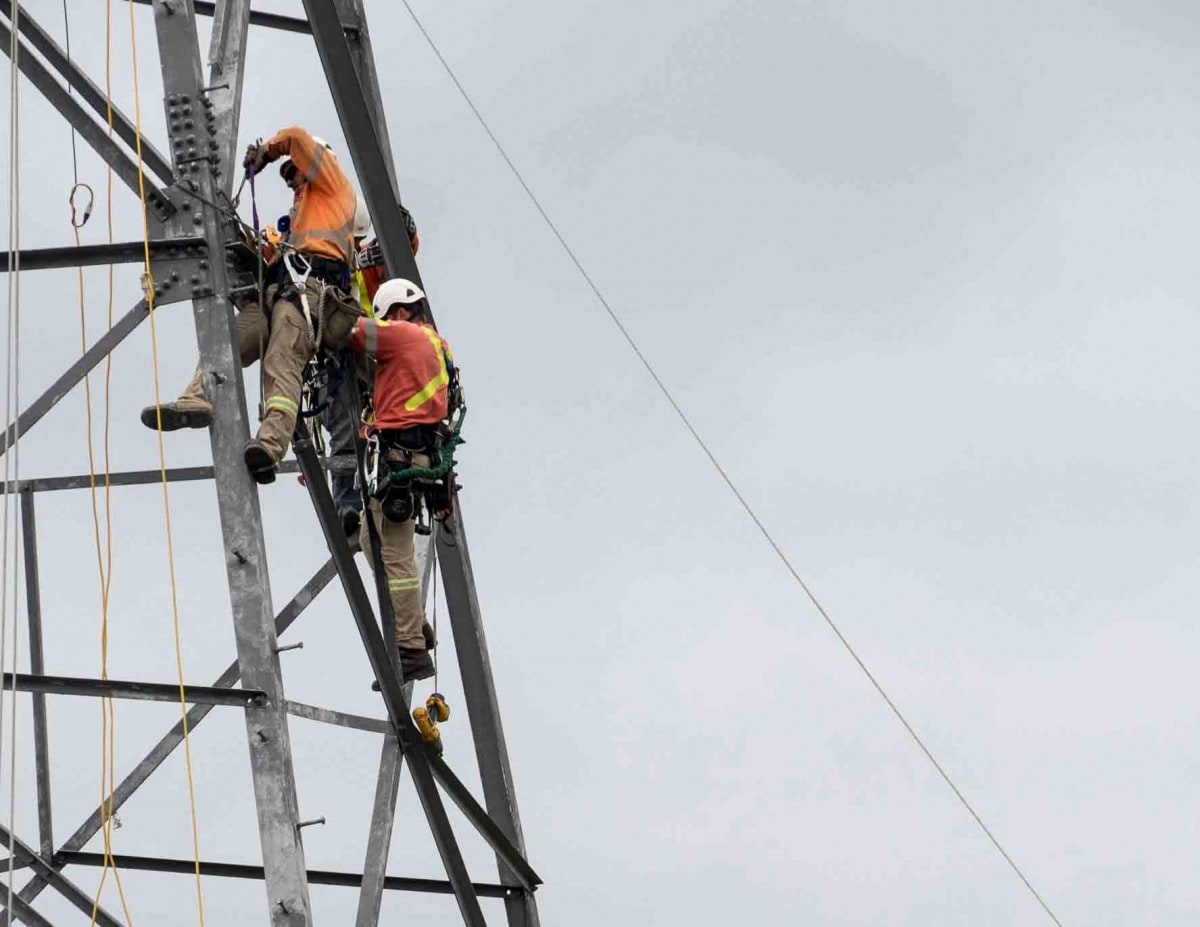

The height of the towers, the weather and no outages on the circuit created several challenges for Allteck. Due to the height of the towers, man-baskets suspended from cranes were required to get workers into position to perform the work as opposed to traditional methods. The use of cranes and the use of elevated platforms were further complicated due to the high winds experienced and the requirement to work in close proximity to an energized circuit, thereby creating the need for planned crane moves.

Specialized Work Methods

Touch and go helicopter transportation to the tower was used, as well as, implosive sleeves on the conductors to install the sleeves. Normally a fixed basket attached the crane would be used, but due to the height of the towers a suspension basket was utilized requiring specific certification procedures and planned movements of the crane.

Client: Northern British Columbia client

Owner: Northern British Columbia owner

Category: Transmission

Location: Kitimat, BC