High Pressure Pipe Type 69kV Cable Termination Repair

The Project

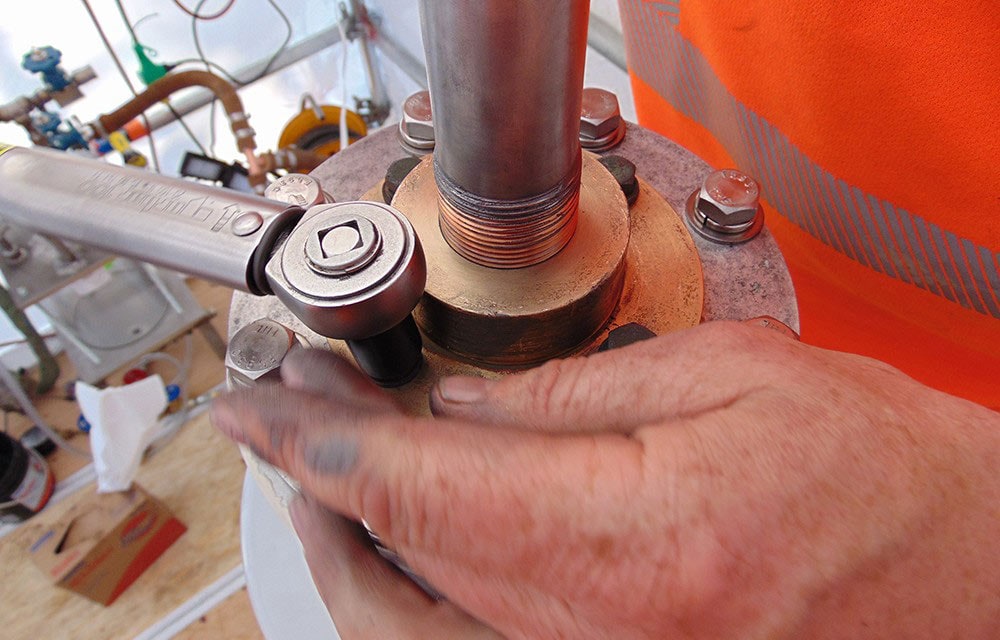

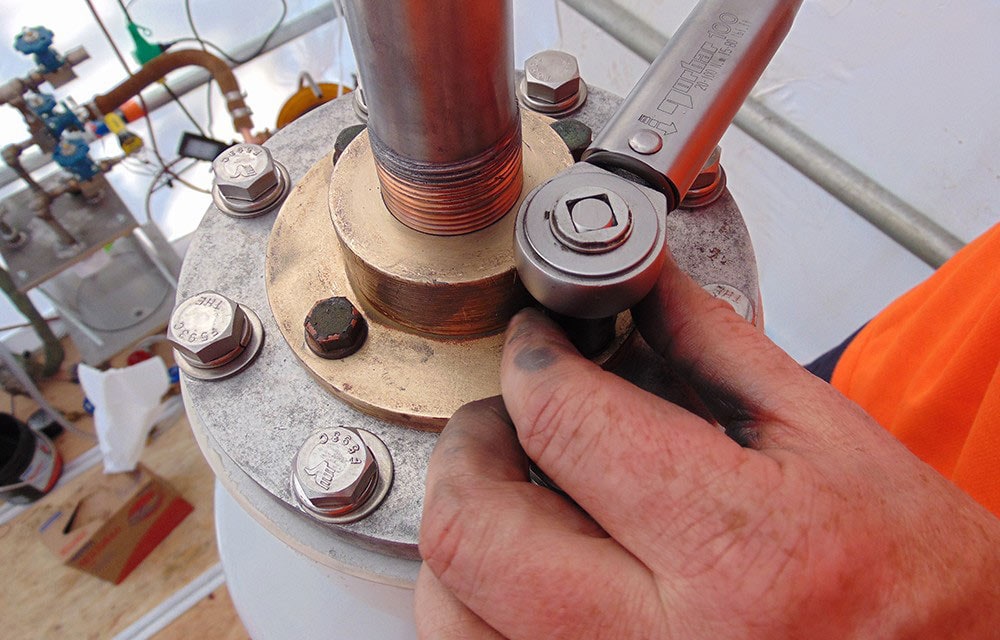

Canfor Pulp Mill hired Allteck to replace a leaking high-pressure Canada Wire type termination. This termination was built in 1964 and was subject to severe corrosion issues which resulted in a cable oil leak. Allteck’s high-voltage installation crew carried out the replacement of the termination and utilized specialized oil purification degassing equipment to purify the existing cable oil. Some additional equipment used in the repair was a rotary vane vacuum pump, a digital vacuum impregnation, G.V.E Vacustat, and automatic drain bottle with the use of specialized valves, gauges, fittings, and an oil dielectric testing apparatus.

The termination was successfully replaced and the cable oil was topped up to operating levels. Pressure gauge readings were then taken at the feed tank end indicating the cable circuit was returned back to the correct operating pressure at 1379 KPa. High voltage test engineers then performed all tests requested by the customer. The test results indicated much better readings on the newly refurbished termination than the previous operation.

Client: Canfor Pulp Mill

Owner: Canfor Pulp Mill

Category: Underground Cable

Location: Prince George, BC